325 N. St. Paul Street Suite 3100 Dallas, Texas 75201

(866)-225-1071

Aircraft Fatigue Analysis - Welcome to Air Craft Certs

- Home

- Aircraft Fatigue Analysis

Aircraft Fatigue and Damage Tolerance| Acert

- TOOLS: NASGRO, AFGRO

- Classical Analysis Techniques

- Damage Tolerance

- Material Fatigue Properties Development

- Fatigue Load Spectrum Development

- Rainflow Counting Algorithms

- Non-Destructive Testing and Evaluation

- Fracture Control Planning and Implementation

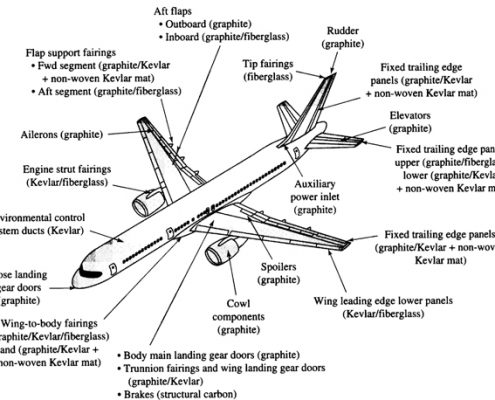

Full Inspection of all aircraft components allow safe repairs of minor damage. We know what can remain in place and what parts must be discarded. Incidental damage (scratches, gouges, and dents), may serve to initiate a crack and ultimately a fatigue failure. Let Acerts help you to remove the harmful effects of this damage by blending it out over a larger area.

Remediation analysis is used to decide what repairs should and should not be made. Because these parts are often fatigue-critical, testing should be used to backup any recommendations obtained from the analysis. Remediation analysis involves a process, which includes the expertise and judgement of the inspectors.In fatigue, a 5% difference in stress can be a significant difference in life, so the analysis must be as accurate as possible. As many of our clients can attest, our analysis are accurate and dependable.

This starts with a firm understanding of the part, especially its historical testing, failures, and loads. At Acerts we verify fatigue FEA analysis methodology and compare life calculation methods. We evaluate the effects of a change in part on endurance limits. part life, and reliability. We can help develop a new interactive new flight test data base on your need.