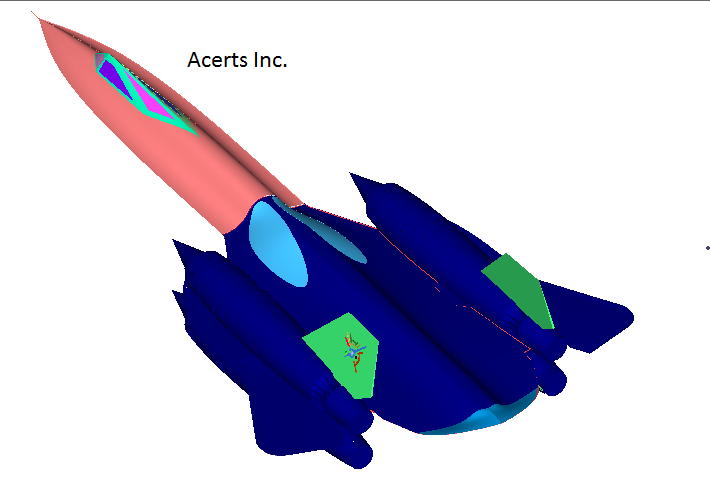

Acerts Inc., we develop new products and manufacturing processes. We provide Dynamic crash analysis services in advanced composites using high end software such as LS_Dyna and Abaqus. Acerts offers solutions to government’s agencies and the aerospace industry. We are the quiet partners who stand beside you in getting the project to the finish line or to get an expensive asset back in the air.

Acerts engineering support services: System Engineering, technical support, resources for requirements definition, security assessments, trade-off and feasibility studies, design, development, testing, installation, investigation, creation and verification of technical documentation, plans, and drawings related to technical management concepts; and performance, compatibility, interchangeability, interface, and operational evaluations.

We manage product testing, to include reviewing and creating test standards and specifications; developing Test Evaluation Management Plans, scheduling, identifying necessary assessors, arranging external services, and fabricating thresholds for performance.