325 N. St. Paul Street Suite 3100 Dallas, Texas 75201

(866)-225-1071

Wind Energy - Welcome to Air Craft Certs

- Home

- Wind Energy

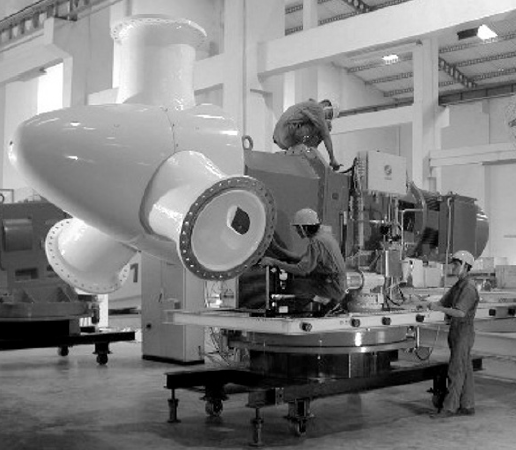

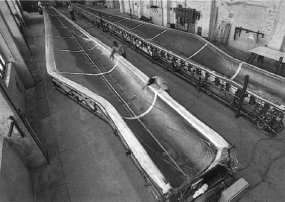

ACert Inc.| Collaboration Hanson heavy Industries

Your needs are a point of reference, as well as a challenge to us. Make the most of our technical know-how, and tap into our great innovative energy and our excellent knowledge of the industry. Experience our versatility for yourself. Our technical skill, quality and innovation, We get things moving: take advantage of our expertise. Our from highly-developed complete solutions to special drives and individual components in the output range up to 45 MW. We offer a comprehensive range of services including drones monitoring, and will do everything possible to ensure that our products optimise your industrial value-added processes and thus contribute to your success. We can respond quickly and flexibly to your needs and are constantly seeking to upgrade our tried and tested products, and to develop new pioneering products for our industry. We achieve this primarily by building upon our innovative cutting-edge technologies and materials. At A_Cert its drones to look for cracks in wind turbine blades, which can hang hundreds of feet above the ground. Major oil companies has deployed A_Cert drones and thermal cameras in Alaska to scan oil pipelines for hot spots that may indicate structural weaknesses. Thanks to our highly effective electrical and mechanical design departments at heavy industry Gear Box manufacturing in MI, wind power generators can be tailored to meet the individual needs of their operators; our development departments work hand in hand with partners from the areas of science and research. The resulting products are among the technical leaders in the market, and will play a major part in providing a benchmark for the next generation of products for wind power plants. An important factor in our success – quite apart from our flexibility, vertical range of manufacture, modern technology and quality awareness is our highly-qualified and motivated workforce. This ensures that our customers benefit from continuity and dependability in the long term.

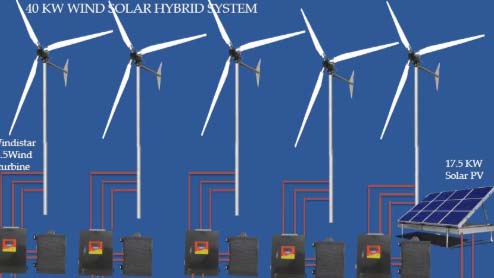

Wind Power Financing

ACerts offers a lower, predictable cost of energy with no upfront costs. Learn more about our wind power commercial financing. $0.0 no upfront cost to you. Wind power Lease $0.0 no upfront cost to you.

Wind Farm Project Planning & Estimation of the wind regime

In course of the site selection the estimation and assessment of the wind regime is of prime importance since, as already mentioned several times, if the mean wind speed is 10% less than estimated the energy yield may be reduced by 30% and more. The first step includes the assessment of the determined wind speed values obtained e.g. by general meteorological data, and moreover the verification of the orography at the site, the terrain structure, the surface roughness and as well the type and size of the terrain boundaries. Moreover, single obstacles like rows of trees or other wind turbines have to be registered exactly. Even at this stage, it is necessary to consult an experienced planning expert who should then determine the further procedures and methodologies to be employed for the detailed determination of the wind potential. Different procedures for the site assessment were presented Depending on the local conditions but also on the quality of possibly available regional wind data, e.g. from measuring stations, the applicable method is chosen and decided to which extent own wind measurements are required. First estimation of the installed capacity and expected energy yield Apart from the available area of the site, the available grid connection is a decisive factor in determining the number and rated power of turbines to be installed. Therefore, it is reasonable to send an inquiry to the local grid operator at an early stage in order to check the possible grid connection capacity, the distance to the next potential feed-in point and the voltage level of the grid connection it may be reasonable or necessary to build a separate sub-station for larger capacities (> 20 MW). These two boundary conditions (available area of the site and grid capacity) may be used to estimate the number and rated power of the wind turbines which then forms the basis for the initial prediction of the expected energy yield. In wind farm planning the yield is predicted for each wind direction sector individually using its individual wind frequency distribution function and the power curve of the chosen wind turbines. This is necessary in order to find the optimum placing of the wind turbines in the micro-siting of the wind farm which gives the maximum wind farm energy yield and also reduces the inevitable interactions of the wind turbines.

Automatic Activation.

OUR power guide comes standard with all ACerts power systems. We install the hardware at no extra cost, and it’s activated automatically when your system is turned on. You can view your power system performance at easy access around the clock and converted in dollars into your Bank account

ACerts provides unprecedented visibility into your system’s power generation and your operation’s energy consumption. It provides around the clock of your system’s key solar performance metrics to ensure your systems are producing as promised and automatically notifies us if it isn’t, so we can address any issue

A Cert Heavy Industries Windmill download PDF File

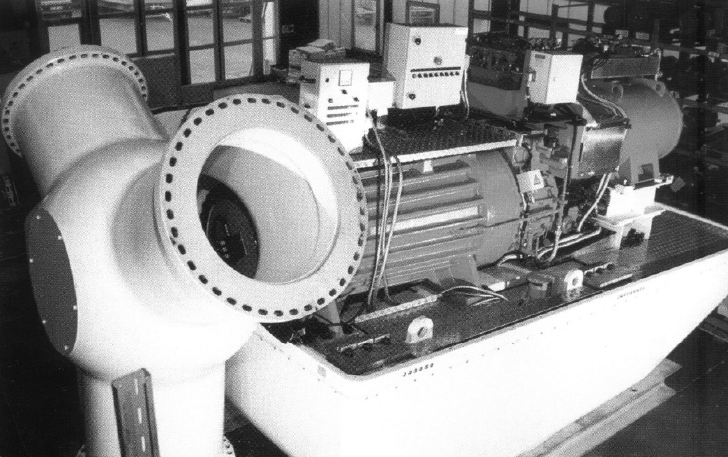

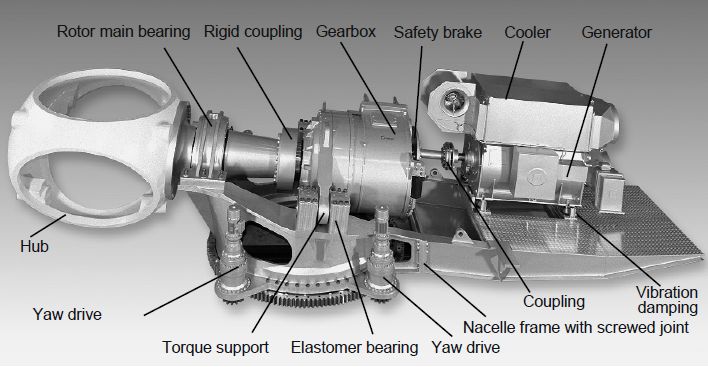

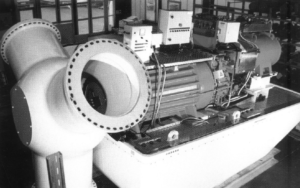

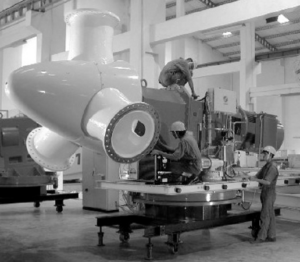

The industrial applications of our electrical machines and the years of experience which feed into their design have proved invaluable when developing and precision manufacturing our wind power generators in particular. Our product line of double-fed wind power generators can be customized as required. The close cooperation we enjoy with leading manufacturers of frequency converters means that optimal solutions can be found for every plant configuration. Wind power generators are adapted to meet individual customer requirements by our technical engineering department, based on the standard components of electrical machinery manufactured by Hanson Heavy industry.

The application of modern electrical design programs optimum efficiency, even in the partial load range, and reduced noise levels. Specific site conditions (weak electricity networks, reactive power to other grid codes). The life of the generator is motorized through weekly maintenance report of the all the wind mill parts by internet if you sign up our lifetime warranty plan, depending on the respective nacelle design.

Double-fed 2.5 MW wind power generators designed for a voltage level of 3.3 kV have been designed for offshore and output 25.2 MW, and for a generator output of 5.4 MW, This wind power generator with its rated voltage of 950 V has also been developed for offshore use. There are now several thousand wind power generators in operation throughout the world. Double-fed machines with a capacity of 1.5 MW in particular have been series produced for years and are supplying the grid with the power they generate, a case in point being the large US wind farms in CA and TX. Please call us for price and availability.

ORDER WIND TURBINE SPARES ONLINE

Acert Inc. is Hanson heavy industry the leading wind mill company we provide servicer for our buyers and sellers in the wind turbine aftermarket. On our platform, there are more than 10,000 parts, for faster service immediately contact our team. On the platform you will find more than 10,000 new, used and refurbished spare parts suitable for wind turbines manufactured by Vestas, Gamesa, GE and others. All the products are provided by the best suppliers, carefully reviewed by the Spares in Motion team, to guarantee reliability and transparency.

Offshore Wind farms

As a rule of thumb from the offshore oil and gas industry any work on sea is five to ten times more expensive than on land. In general, economically feasible offshore development depends upon viewing offshore wind farms as larger systems that are composed of integrated sub-systems This chapter is organized along similar lines and addresses the various sub-systems in order to construct an overview of offshore wind energy development However price of new material given us edge for produce cheap. In year 2000 the price composite material was $2000 per lbs.

Due fastest growing demand we are able produce some of the composite material at $7 per lbs. The major challenges the offshore market must be large enough now the time of the marketability of the wind turbine in order to make the development of a product purely designed for offshore conditions profit-able. If Acerts gets investment PO for the wind farm installation to shallow water into the red sea or Arabian shallow sea near Karachi they can create a major job market in the area at both location. The offshore market must be large enough at the time of the marketability of the wind turbine in order to make the development of a product purely designed for offshore conditions profitable.

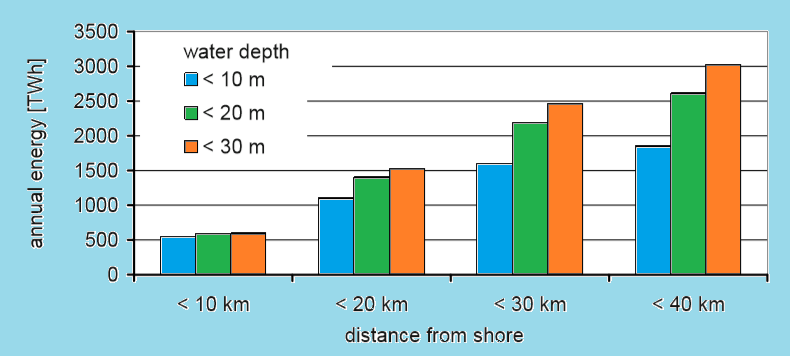

Wind energy will be playing a dominant role in raising the share of renewables in electricity generation. This will significantly reduce the emission of carbon dioxide and the use of fossil fuels. Land use limitations in areas with high population density are hindering the installation of new large wind farms. Offshore, however, there is an enormous wind resource that has the advantages of both abundant space and dense winds. In 1995, a collaboration study was done by Acerts Inc. that the exploitable offshore wind resource theoretically exceeds the total consumption of electricity in Europe. First smaller scale offshore wind farms were built between 1991 and 1997 in Sweden, Denmark and the Netherlands. Intended as demonstration projects, they were installed in relatively sheltered waters. The year 2000 marked the start of commercial offshore development with the erection of the first sea-based wind farms employing 1.5 to 2 MW wind turbines at water depths below 10 m. In 2002, the first large offshore wind farm, with 160 MW capacity, was commissioned in Denmark. 631 offshore turbines with a total capacity of 1,486 MW have been erected by the end of 2008. This corresponds to 1.2% of the total cumulative wind power capacity in the world. For the distant future, plans have been developed for Gigawatt-sized plants that employ multi-megawatt machines at sites as far as 100 km from shore and in water depths up to 30 m. The aggressive environment of the North & Atlantic Ocean will present real challenges compared to the relatively benign Baltic. Eventually, the installed offshore capacity may amount to several times that installed on land. The aforementioned demonstration projects proved the technological feasibility, but highlighted the economic challenges associated with sea-based development.

Offshore environment

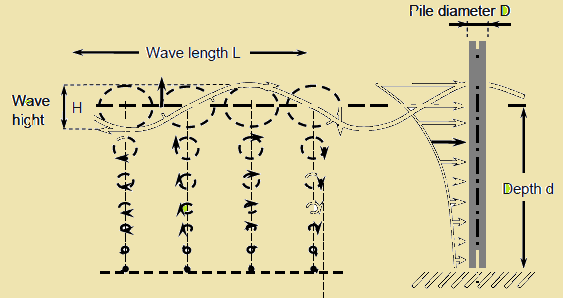

Various natural and man-made environmental conditions can affect an offshore wind farm and these conditions create both incentives and challenges. Offshore development is attractive because the annual average wind speed is considerably higher offshore than at most onshore sites and the lower surface roughness at sea causes a lower ambient turbulence. The most important consequence of the harsh offshore environment is the high design requirements. Turbines must be able to function unmanned over a long repayment period (up to 20 years) at a remote location that is difficult for maintenance personnel to access. We illustrate some fundamentals of wind-induced wave loading. Generally, one has to distinguish between sea conditions generated by local winds and swells originating from waves that have travelled a long distance. The topography of the North Sea and the Baltic Sea, for instance, leads to less significant swells. The periods of energy-rich waves range between 2 s and 20 s. The energy of a sea state is proportional to the square of the significant wave height which itself is proportional to at least the second power of the zero-crossing period. Extreme waves have long periods, typically 7 to 13 s. Nonetheless, waves of moderate height are most important for dynamic wave loading and associated fatigue since their occurrence is high – 1 to 5 million waves per annum – and their periods are closer to the fundamental natural period of the structure.

For large offshore wind farms, however, the latter advantage might be partially offset by the wake-induced turbulence and background turbulence of the wind farm itself. Though the favorable wind regime invites development, the offshore environment makes development technically complicated. Waves, currents and sea ice generate the most important hydrodynamic loads. The sea level varies according to tides, atmospheric conditions or long-term trends. Behavior of offshore foundations is more complex for a variety of reasons. From both a practical and a theoretical viewpoint it is much more difficult to get reliable soil parameters for design purposes.

Also, waves and currents may erode soil in the vicinity of the foundation (scour) or may destabilize the entire seabed. And the high humidity and salinity increases corrosion of machinery and structure but don’t warry our engineering have experience implanting low cost solution at your current and further windfarm in order to protect taxpayer dollars/private investments.

At Acerts we believe that the offshore environment places demands on wind turbines that are not present in an onshore context. It is also evident, however, that offshore wind turbines, above the height of the wave impact, are not very different from onshore machines. Our two technical approaches have been taken in developing offshore wind turbines: the robust and proven onshore solutions and the offshore-specific concepts into radical new designs.

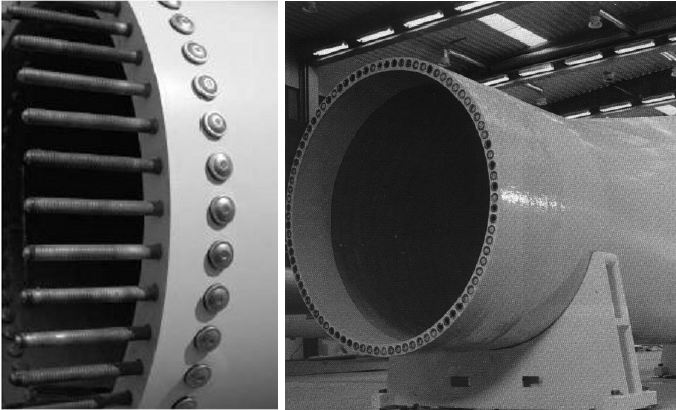

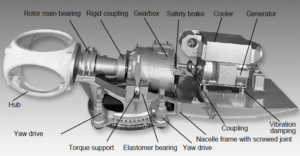

In the onshore designs when they are transferred to offshore sites: maintenance aids that enable on-site repair of some components are added, climate and corrosion protection for the nacelle is improved, control capabilities are enhanced, and the specific rating, i.e. installed capacity per swept rotor area is partially increased. An air-tight nacelle is some-times proposed but this obliges to employ external heat exchangers for the gear-box, the generator and the power electronics. In addition, an air-tight nacelle re-quires an expensive and energy-consuming cooling system for the other smaller sources of radiated heat. For these reasons, most designs rely on a high standard of corrosion protection and the capsulation of individual components instead of an air-tight nacelle. The RE power 5M, which was first built in 2016, is an example for a turbine using a conventional design concept in the 5 MW class.

Again two different trends have emerged from the integration of offshore requirements into the design process: a focus on reliability and serviceability and the development of advanced lightweight composite, high-tip-speed designs. Another example of new design concepts is the 5MW turbine which was first installed as well. The weight of the nacelle is reduced by using a highly integrated drive train. Moreover, it features the avoidance of high-speed stages of the gear-box by matching a one-and-a-half-stage planetary gear with an intermediate-speed synchronous generator with super low speed permanent magnets. So this drive train concept is situated between the traditional Direct-Drive design and the commonly used designs with a multi-stage gearbox with a high-speed genera-tor. The nacelle of the 5MW is enclosed against the maritime environment and cooled by heat exchangers.

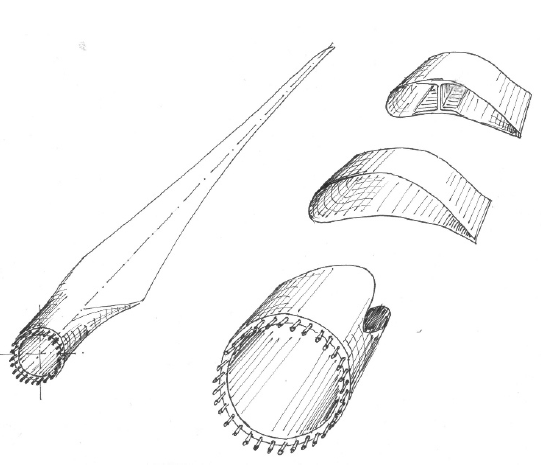

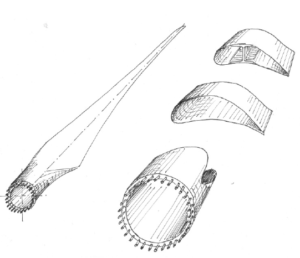

The ongoing rapid growth in turbine size and the need to base production on proven technology favor’s the horizontal axis, upwind-oriented turbine design that is used in land-based solutions. Though all offshore turbines are currently three-bladed designs, advanced two-bladed concepts might be applied at a later, matured stage. Two-bladed turbines have several advantages over three-bladed designs. First of all, two-bladed turbines are comparatively simple to install and maintain. Also, relaxed noise limitations offshore enable the use of a higher rotor speed, which reduces both the dimensioning torque for the drive train and the transmission ratio of the gearbox. Lower blade solidity is optimal for higher speeds and this can be achieved by omitting the third blade. Despite these advantages, how-ever, the complicated dynamic behavior and the alternation of high loads are major challenges.

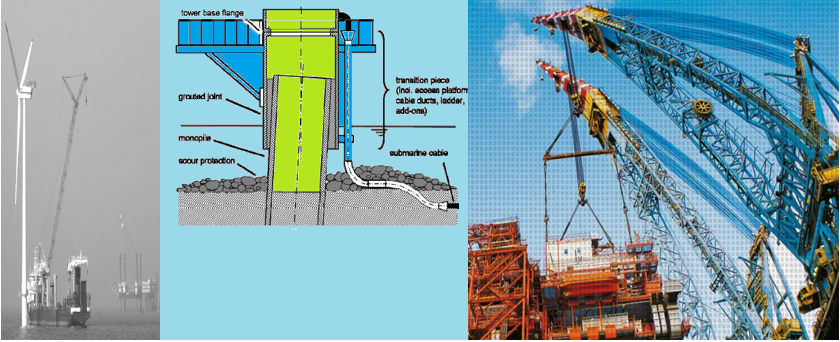

Marine Installation

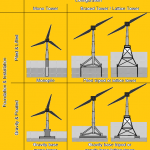

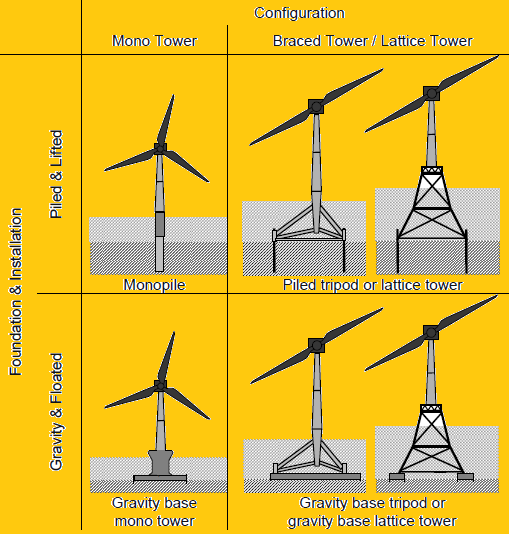

The turbine support structures. The integrity of tower and marine foundation, are the most obvious differences between offshore and land-based wind turbines. Ferguson classifies offshore bottom-mounted support structures according to three basic properties structural configuration, foundation type and installation principle. Any structural concept, including

- Monotowers

- Braced towers

- Lattice towers

Can be reasonably combined with either a piled or a gravity foundation. From a logistical point of view, however, it is beneficial to match piled designs with lifted installation and gravity foundations with floated installation

Driven or drilled, steel mono piles are currently the preferred solution. They are economically attractive for use with the 2 to 3 MW class in water depths of approx. 20 m, and for use with 5 MW designs in depths up to 15 m. For larger depths, tripod, quadruped or lattice structures are needed. In 2006 the first jacket foundations for offshore turbines have been installed in 45 m water depth in Scotland Gravity foundations have been applied mainly at shallow

DanishSite where high ice loads and particular soil conditions prevail. For other sites, such devices are more expensive. Dismantling and depositing might reduce the prospects for future use as observed recently in the oil and gas industry. Floating offshore wind turbines have been proposed for water depth of larger than approximately 50 m but are unlikely to material is in the medium term because of the extraordinarily high costs for the moorings and the complex dynamic behavior.

To reduce the high cost, the design must be optimized with respect to a particular turbine, local site conditions, batch size and the particularities of offshore wind energy. The dynamic characteristics of the support structure are of particular importance to offshore design. With this in mind, a compromise between the opposing requirements of the wind energy and offshore communities has to be found. Wind turbine towers in the megawatt class are slender and flexible structures with a first natural frequency below 0.45 Hz. Common offshore structures of the petroleum industry employ a significantly higher natural frequency since dynamic wave loading is strongly reduced for structural frequencies above approx. 0.4 Hz.Most designs for multi-megawatt turbines will be governed by aerodynamic fatigue or by a combination of aerodynamic and hydrodynamic fatigue. Sophisticated design approaches are required which integrate the experience from both the offshore oil and gas industry and the wind energy community. Scarce equipment, high mobilization costs, weather delays and safety requirements make any offshore operation very expensive and logistically complicated.

For Price and Estimate Please call The price of the composite are down to $7 per lbs.

For the purpose of estimating the costs of the foundation, typical values for the specific costs (per kW installed capacity) are available. For a flat foundation they vary between approx. 70 and 100 €/kW depending on the hub height of the wind turbine. If the geotechnical investigation report for the site reveals that the bearing capacity of the ground is not strong enough, additional measures are required a piled foundation) which increase the costs significantly compared to those of a standard flat foundation. The costs incurred by the access lanes and roads again vary strongly depending on the local site conditions and the optimum wind farm layout. The bearing capacity of the access lanes, and therefore the specific costs in € per metre, are determined primarily by the transport weight of the cranes. They also depend on the wind turbine size. It must be differentiated between the access requirements which exist during erection and those emerging from wind farm operation. Nevertheless, access for cranes should be ensured in case larger repairs need to be carried out at a later stage. The costs for planning, permission and indemnification measures and so-called „soft costs“ for the foundation and organisation of the operating company, as well as the financing costs, are in the order of 3 and 6% of the total investment costs for wind farm projects in Germany. The first measure used to compare different wind farm projects is the powerspecific investment costs index SIKL = Total investment costs / installed capacity in €/kW. (15.2)

However, this index does not provide any information on the yield potential of the site, i.e. the annual energy yield or production. Therefore, the second measure yield-specific investment costs index:

SIKE = Total investment costs / annual energy yield in €/kWha (15.3) In Germany, typical values of the power-specific investment costs index are around SIKL = 1,100 €/kW, and for the yield-specific investment costs index in the range of SIKE = 0,50…0,75 €/kW The type of financing plan is of particular importance when assessing the economic efficiency of a wind farm project. A typical example of a financing plan for a wind turbine with a rated power of 1.5 MW. The required share of equity is set by the financing bank which also submits an application to the KfW Bankengruppe (Kreditanstalt für Wiederaufbau) and Deutsche Ausgleichsbank (DtA, merged with KfW in 2003) for the loan with reduced interest under the umbrella of its ERP environmental and energy efficiency programme.The share of equity varies slightly depending on the site quality and the financial standing of the investor. A higher share may be fixed if there is a higher financial risk due to a lower site quality or reduced financial standing of the investor.

Investment costs Value Unit Share or comment

Wind turbine (incl. Crane and erection) €1,432,000

Foundation €51,000

Access lanes € (400 m) 15,000

Substation 77,000 € 4.4%

Grid connection (1000 m) € 77,000

Planning / Site supervision €31,000

Site (land lease) 0

Miscellaneous €31,000

Business / tax and legal consultancy €31,000

€1,744,000

Financing Annual proceeds

Wind speed at hub height 6.37 m / s

Calculated annual electricity production 3,074 MWh / a

Availability of wind turbine 98%

Effective annual electricity production 3,013 MWh / a

Reference yield (EEG-quality of site: 91.6%) 3,288 MWh / a

Feed-in tariff (for 18 years until ’09 2018) 0.091 € / kWh

Feed-in tariff (for remaining 2 years 0.062 € / kWh

Feed-in tariff (average for 20 years) 0.088 € / kWh

Annual feeding-in proceeds (average) 265,400 € / a

Annual expenses

Capital costs (annuity) 158,000 € / a

O&M costs 7,700 € / a

Insurance (machine, 0.6% wind turbine cost) 9,200 € /a

Insurance (BMU, 0.9% of annual yield) 2,600 € / a

Power consumption / telecommunication 1,500 € / a

Land lease 7,700 € / a

Administration (1.0% of invest. costs) 17,400 € / a

Reserve / repair (2.0% of invest. costs) 34,800 € / a

Miscellaneous (0.5% of invest. costs) 8,700 € / a

247,500 € / a

Imputed annual net income

Annual feeding-in proceeds (average) 265,400 € / a

Annual expenses (calculator) 247,500 € / a

Surplus 17,900€ / a

Decommissioning and repowering of wind turbines or Repair

At Acerts you get factory repair with the option to upgrade. The operating period the wind turbine has to be decommissioned. Another economic alternative is so-called repowering which is the replacement of many small wind turbines by a few bigger ones. The local options for this should be checked carefully already in the wind farm planning because decommissioning or repowering should be considered in the contracts. New wind turbines are not only bigger than smaller ones. Typically, they are more quiet and more efficient almost two time more production, showing higher availability and energy yield at the same site and as well as reduced service costs. Therefore, repowering brings technical progress and economic benefits. Moreover,a few big wind turbines have a reduced the visual impact on the landscape compared to the case of many small wind turbines. First and foremost, repowering is a decision based on economic considerations. Mostly, it is only economically viable after 20 years of operation. However, several successful repowering projects in Germany have already proven the increased economic benefit as well as the reduced visual impact Legal aspects In order to implement the wind farm project and operate the wind turbines, it is necessary to establish a company, since operating wind turbines implies a commercial venture.several successful repowering projects in Germany have already proven the increased economic benefit as well as the reduced visual impact Legal aspects In order to implement the wind farm project and operate the wind turbines, it is necessary to establish a company, since operating wind turbines implies a commercial venture.several successful repowering projects in Germany have already proven the increased economic benefit as well as the reduced visual impact Legal aspects In order to implement the wind farm project and operate the wind turbines, it is necessary to establish a company, since operating wind turbines implies a commercial venture.

For a small wind farm with only a few participators a partnership under the German Civil code. The formation of company does not require much effort as no formalities are involved except for registration with the tax office. There is no need for the minimum capital or the registration in the commercial register. However, the partners concerned are commercially liable, meaning that they together with their entire personal assets

Typical cost break-down of an offshore wind farm with 5MW wind turbines Component Approx. cost share

Rotor-nacelle assembly incl. transformer, switch gear 33-50% *)

Tower 5%

Foundation (tripod) 15-18%

Foundation piles (site specific) 2-6%

Offshore installation (incl. weather risk) 5-7%

MV submarine cables (within cluster) 2%

HV submarine cables (shore connection) 2 – 20%

Offshore sub-station 4-10%

Onshore grid connection 4-10%

Planning, certification, due diligence 4-7%

Financing incl. interim financing 3-6%

*) actual contribution depending on amount of total project costs

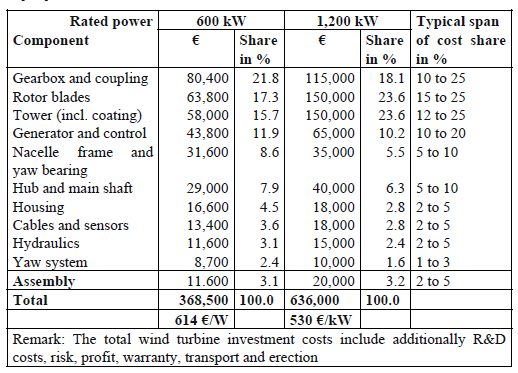

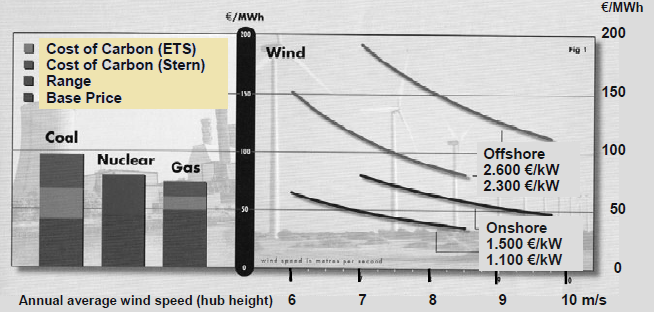

The electricity generation cost for different power sources including financing and operation and maintenance costs are presented in Fig. 16-13. Increasing prices for raw materials like steel and copper as well as the high demand for wind turbines have caused an increase in wind farm costs of up to 30% during recent years. Even taking this into account, wind energy at good sites on land is cost competitive with newly installed conventional power plants. Offshore the specific investment costs in $/kW are about twice as high as onshore. Therefore, the higher energy yield of sea-based plants only if countries interested can compensate the larger investment and running costs. Typically, generation costs offshore are 50-100% higher than on land. Hence, further technological development and economy of scales are badly needed to improve economic viability.

Despite these disillusioning economic facts, the necessity to reduce carbon dioxide emissions and fossil fuel consumption results in political incentives to foster the future large-scale exploitation of offshore wind resources. The German Energy Feed-in Law (2009) grants a feed-in tariff which is twice as high offshore as for good onshore sites. Depending on the water depth and distance to shore the power purchase price range is 10-11 ct/kWh. In addition, the considerable cost for connecting.

offshore wind farms to the grid on land have to be covered by the transmission system operator (TSO) if the installation activities are started before the year 2012. This corresponds to an additional incentive of approx. 30% of the generation cost. Every European country operates a slightly than US different incentive system.

Surprisingly, this is more driven by political considerations than by the actual natural resources and site conditions. For instance, in the United Kingdom the installation of new wind farms on land is difficult in the southern part of Britain due to lack of public acceptance, among other reasons. The exploitation of the enormous offshore wind resources is however booming because of both considerably